The automotive industry is no stranger to innovation, and 3D printing has emerged as a game-changer in this fast-paced sector. This cutting-edge technology is reshaping the way vehicles are designed, prototyped, and even manufactured. In this blog, we’ll explore the significant impact of 3D printing on the automotive industry, from enhancing efficiency to enabling unparalleled design freedom.

Prototyping at the Speed of Innovation

Prototyping at the Speed of Innovation

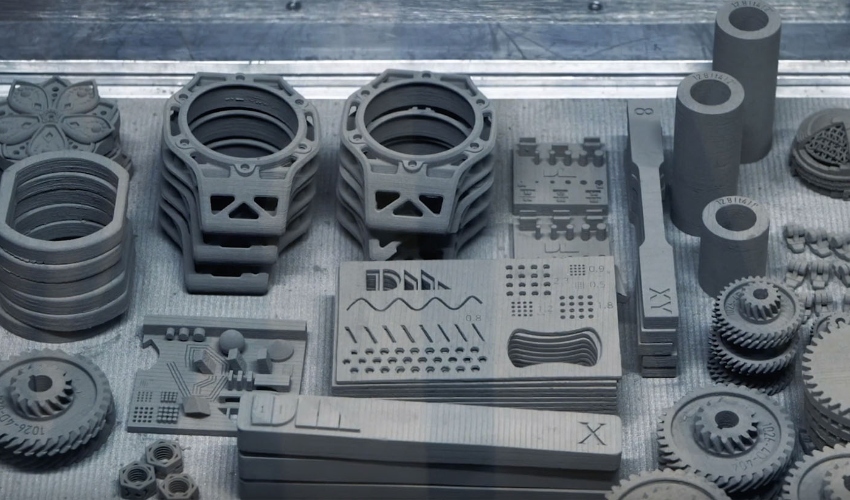

In the automotive sector, 3D printing stands out as a game-changer, particularly in the realm of prototyping. The traditional methods of prototyping have long been plagued by time-consuming processes and high costs. Enter 3D printing – a revolutionary technology that empowers manufacturers to swiftly generate intricate prototypes, facilitating rapid iteration and continuous design enhancements. This not only expedites the product development lifecycle but also slashes costs that were once inherent in conventional prototyping methods.

The Elegance of 3D Printing in Automotive Personalization

Imagine a car that reflects not just a mode of transportation, but a tailored expression of individuality. Enter the world of 3D printing in the automotive sector, where manufacturers are empowered to create bespoke, highly personalized components. From dashboard features curated to match personal preferences to one-of-a-kind exterior designs, 3D printing has shattered the limits of customization in ways previously deemed unimaginable.

Driving Excellence: Unveiling the Benefits of 3D Printing in Automotive Advancements

In the rapidly evolving landscape of the automotive sector, 3D printing has emerged as a transformative force, reshaping traditional manufacturing processes. This blog explores the multifaceted advantages of 3D printing, from enhancing design flexibility to revolutionizing supply chain dynamics.

- Design Freedom and Flexibility: 3D printing liberates automotive designers from the constraints of traditional manufacturing methods. The technology allows for intricate and complex designs that were once deemed impractical. From futuristic car components to streamlined aerodynamic structures, the design freedom offered by 3D printing opens new avenues for creative expression.

- Rapid Prototyping and Iteration: Traditional prototyping methods are often time-consuming and expensive. 3D printing accelerates the prototyping process, enabling quick iterations and design refinements. This agility not only speeds up the product development cycle but also reduces costs associated with traditional prototyping.

- Customization and Personalization: The automotive industry is witnessing a shift towards personalized vehicles. 3D printing facilitates the creation of bespoke components, allowing manufacturers to cater to individual customer preferences. From unique interiors to customized accessories, this level of personalization enhances customer satisfaction and brand loyalty.

- Lightweight and Fuel Efficiency: The quest for fuel efficiency has driven the exploration of lightweight materials. 3D printing excels in creating lightweight structures without compromising strength. By reducing the overall weight of vehicles, manufacturers can improve fuel efficiency, contributing to sustainability and lower emissions.

- Supply Chain Optimization: Traditional supply chains often involve large inventories and long lead times. 3D printing enables on-demand production, reducing the need for extensive warehouses and minimizing waste. This shift towards a more agile and responsive supply chain enhances efficiency and reduces overall costs.

- Cost-Effective Tooling and Manufacturing Aids: Beyond end-use parts, 3D printing proves beneficial for producing cost-effective tooling, jigs, fixtures, and manufacturing aids. Customized tools can be rapidly produced, optimizing the manufacturing process and reducing production lead times.

3D Printing’s Mastery in Crafting Lightweight Marvels

In the pursuit of optimal fuel efficiency, the automotive industry is delving into a realm where lightweight materials and intricate designs reign supreme. At the forefront of this transformative journey is 3D printing, a technological marvel that empowers manufacturers to forge complex and lightweight structures with unprecedented precision. The impact is profound – not merely a reduction in a vehicle’s weight, but a paradigm shift towards enhanced fuel efficiency, elevated performance, and a commitment to sustainable practices.

Concluding the Journey: Accelerating Forward with 3D Printing in Automotive Excellence

As we traverse the innovative landscape of 3D printing in the automotive sector, it becomes evident that this technology is not merely a tool but a transformative force shaping the future of vehicular design and manufacturing. The sequential advantages, from liberated design freedom to cost-effective tooling, paint a picture of an industry that has embraced agility, efficiency, and sustainability.

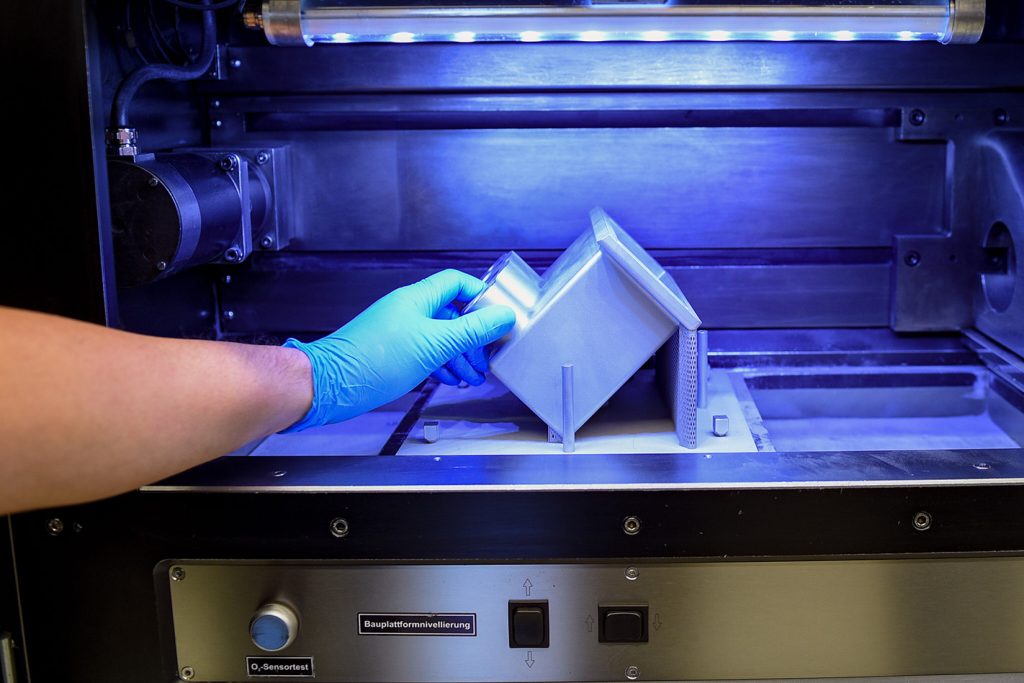

SeekMake provides high quality 3D printing services , ranging from FDM to SLA and SLS, tailored to your unique requirements. We can offer you the perfect solution at a competitive price, whether you need rapid prototypes or large-scale production parts.

With various materials and surface finishes, you will find the ideal combination to fit your needs and demands. Our team of professionals is always ready to provide professional guidance to assist you in making educated decisions. We take pleasure in our dedication to providing our customers with the best manufacturing experience.

Contact us today to get the best 3D printing service. You can also upload your design files to our platform and receive a quote within a few hours.