Simplified Quoting & Operations for Manufacturing Businesses

Rapid, Precision CNC Machining Services in {place2}

Instant quotes and fast delivery in Paris, for prototypes and production parts.

Order your parts in 5 minutes. Get your parts in 8 days.

- All uploads are secure and confidential

CNC Machining in {place2}

SeekMake Network uses state-of-the-art technology to bring custom CNC machining online. We work with a large network of manufacturing partners that together have over 1,600 milling and turning machines, which means we always have capacity and very competitive prices. It also means we can produce both complex prototypes and low-volume production runs of precision machined parts, in a broad range of metals and plastics and with many surfaces finishes too. It’s like having an entire supply chain team for free.

CNC milling

For cost-efficient prototypes and production

- 3-, 4- & 5-axis milling

- Lead times from 5 business days

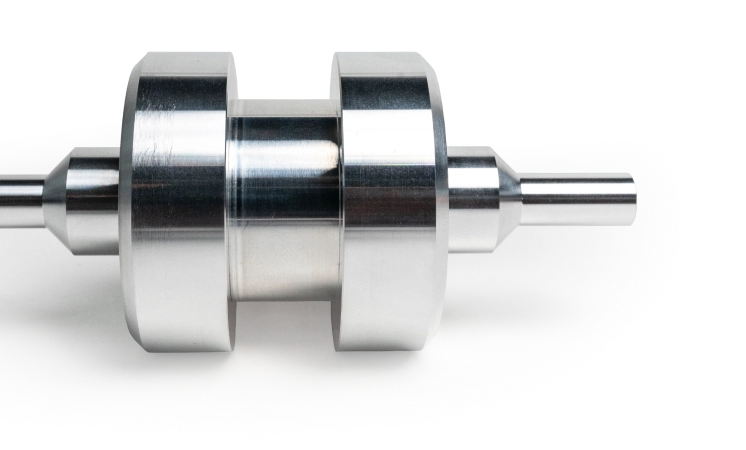

CNC turning

Lathes and live tooling ideal for cylindrical parts

- 60+ metals & plastics, including 10+ aluminum & 20+ steel

- Lead times from 5 business days

CNC machining is the most common subtractive manufacturing technology and a hugely flexible and robust method for producing custom metal and plastic parts. Converting 3D models into G-code, CNC machines remove material from a solid block with various cutting tools. The most popular type of CNC machining is CNC milling, which combines the same computer numerical control (CNC) with a multi-point cutting tool or milling cutter to produce parts with tight tolerances and impressive mechanical and material properties. CNC milling, available in 3-, 4- and 5-axis machines, involves mounting a workpiece to a machine bed and letting automated tools do the rest. It’s ideal for complex design, being one of the most accurate manufacturing techniques on the market. Engineers turn to CNC milling for a huge range of applications, including parts for the aerospace, automotive, consumer electronics and medical technology industries, as well as prototypes and models. While 3D printing offers more design freedom, CNC machining outclasses most additive technologies for low- to medium-volume production, especially with the material range including aluminum, bronze, copper, steel and other engineering metals and polymers.

CNC turning is another popular type of CNC machining, which uses state-of-the-art lathes and turning centers to produce complex, robust custom metal and plastic parts. Using CNC lathes and turning centers, our manufacturing partners can provide cost-efficient parts with simpler geometries. Live tooling is available for more complex geometries and is assessed on a case-by-case basis. Experienced operators use CNC turning machines for operations including parting, boring, facing, drilling, grooving and knurling, in contrast to how CNC milling machines are used. In general, CNC turning is a more affordable alternative to CNC milling and can outspeed milling in cases where the cutting tool’s range of motion is a mitigating factor. It’s important to note that CNC turning isn’t optimal for material conversation, but this is often a necessary trade-in for speed and price. Thanks to the high speed of turning tools, parts will have a lower roughness than milled components.

CNC machining is an ideal process for producing custom parts with tight tolerances and high levels of precision. The only potential downside is that CNC parts often require post-processing to erase tool marks and improve their surface finishes for cosmetic and functional purposes. Applying the right surface finishes can improve your part’s surface roughness, cosmetic and visual properties, wear and corrosion resistance and a lot more. SeekMake Network offers a wide range of surface finishing options, including smooth and fine machining, anodizing, polishing, bead blasting, brushing, black oxide, chromate conversion coating, electroless nickel plating and powder coating, as well as many other more specialized post-processing methods for niche industry applications. Every surface finish has its advantages and drawbacks, so choosing the right one depends on several factors. It’s important to evaluate how your part will be used and in what kind of environment to make the best determination. You can choose from a variety of surface finishes in SeekMake Network’s quote builder and contact contact@seekmake.com for more information.

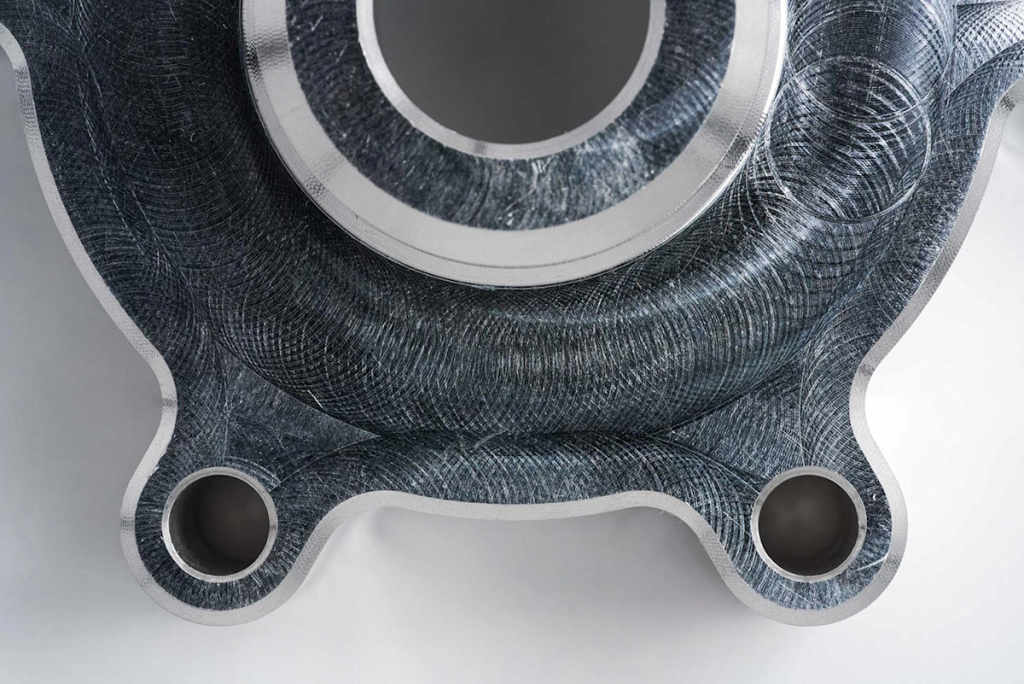

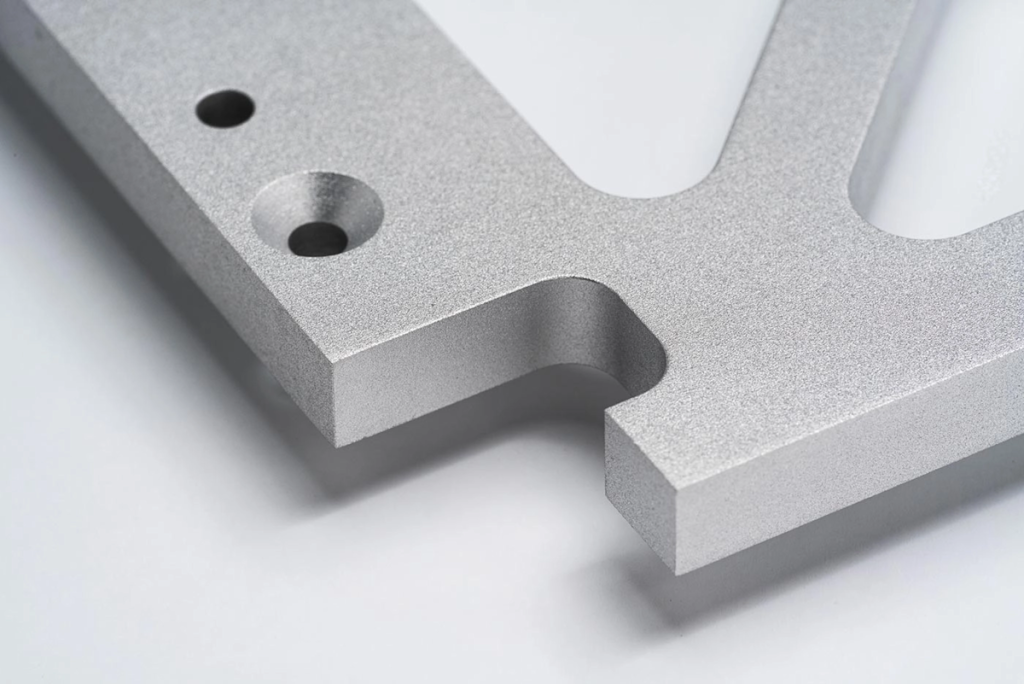

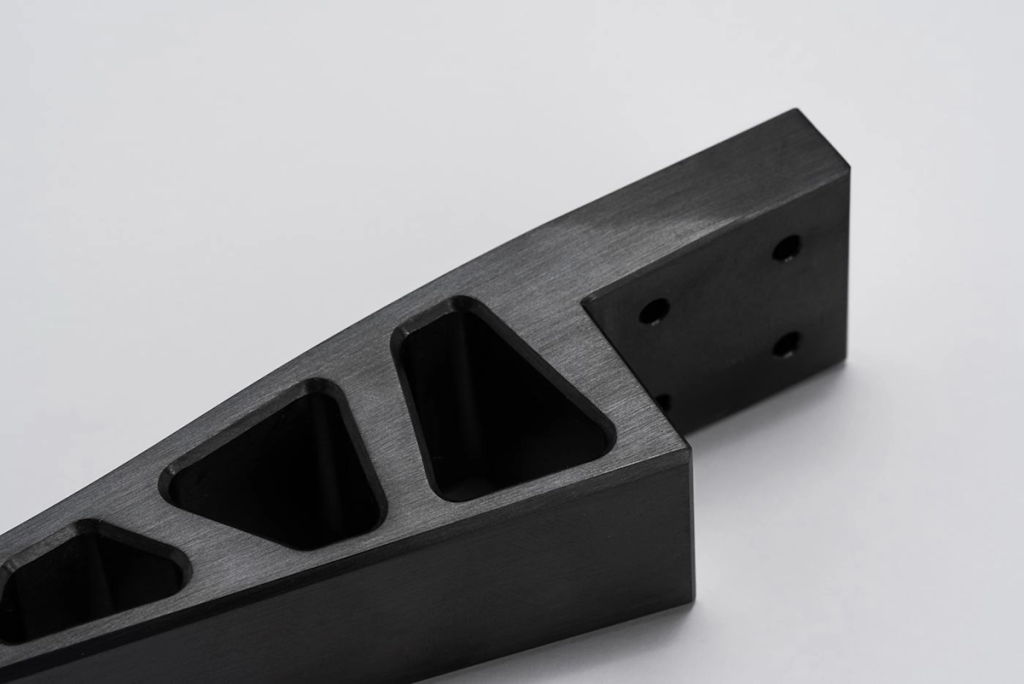

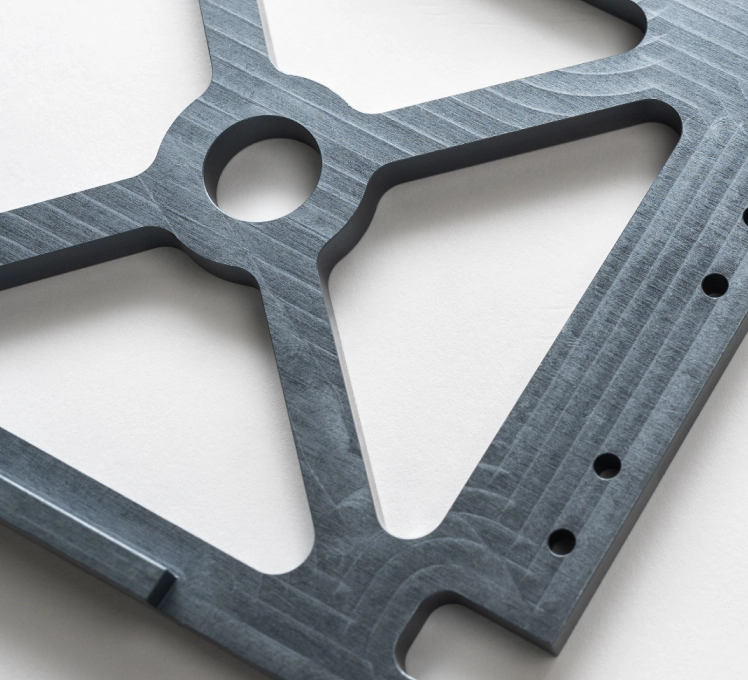

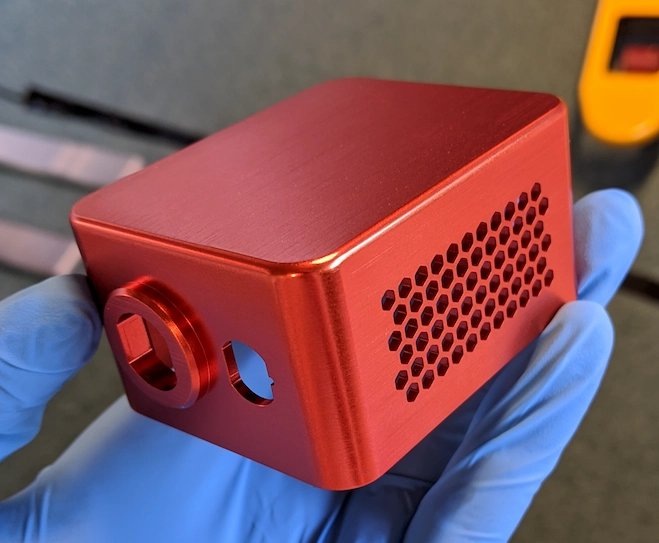

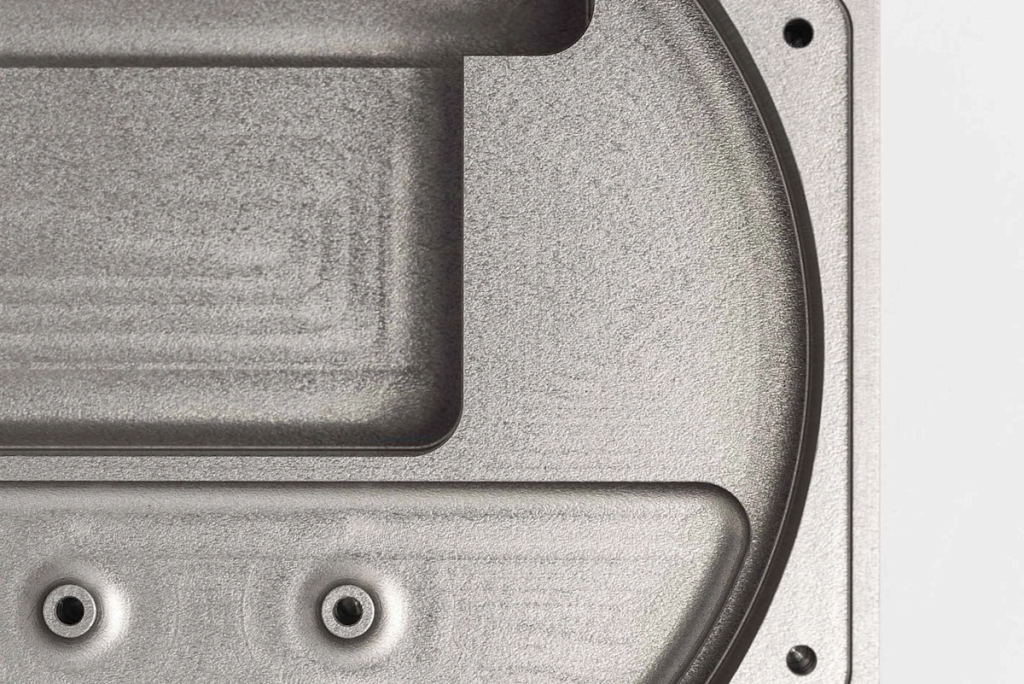

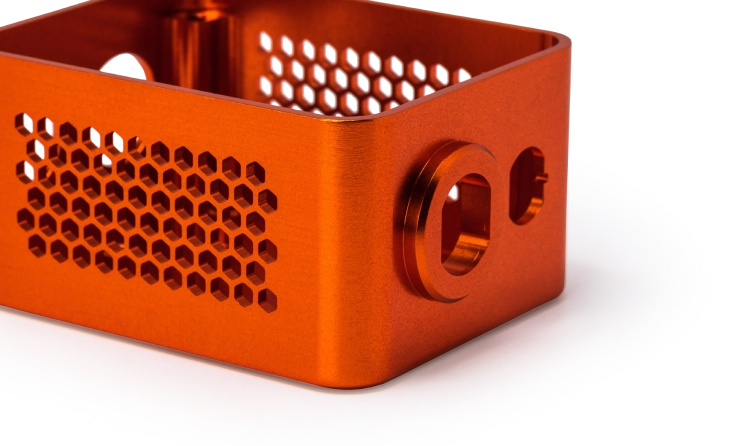

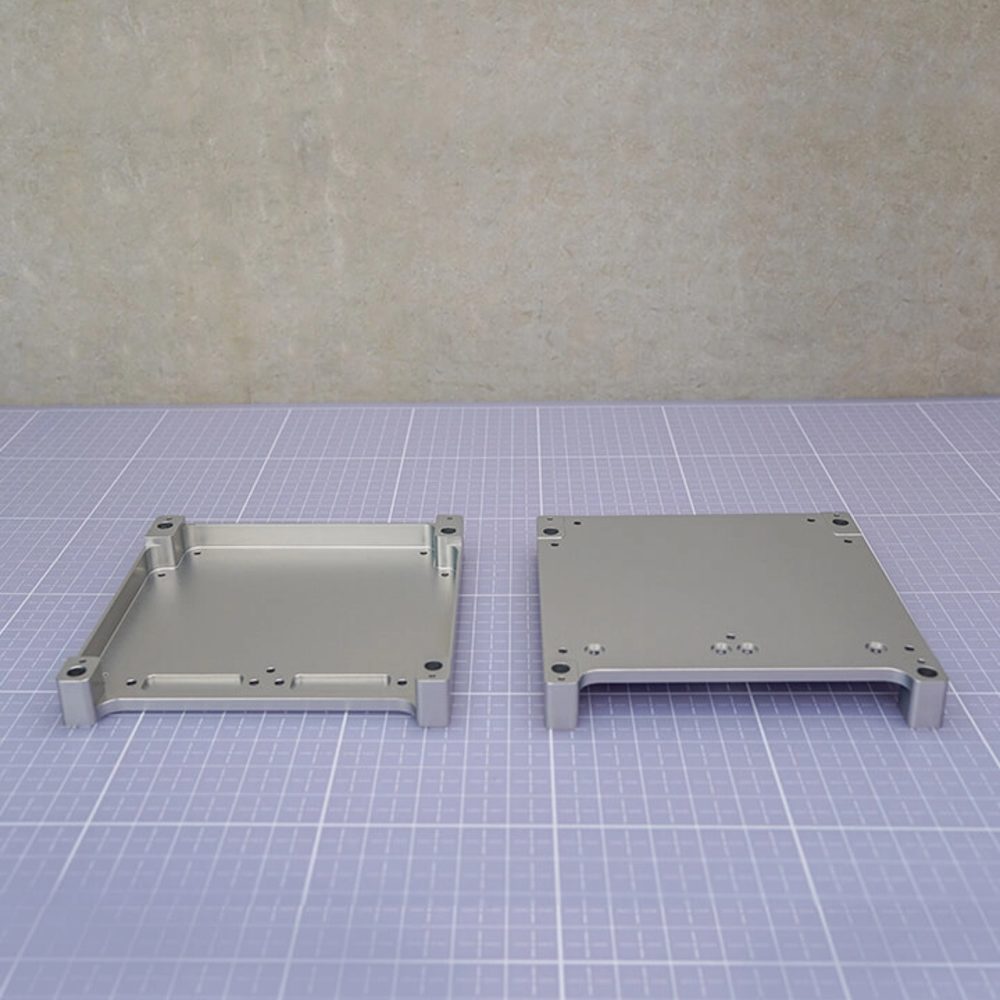

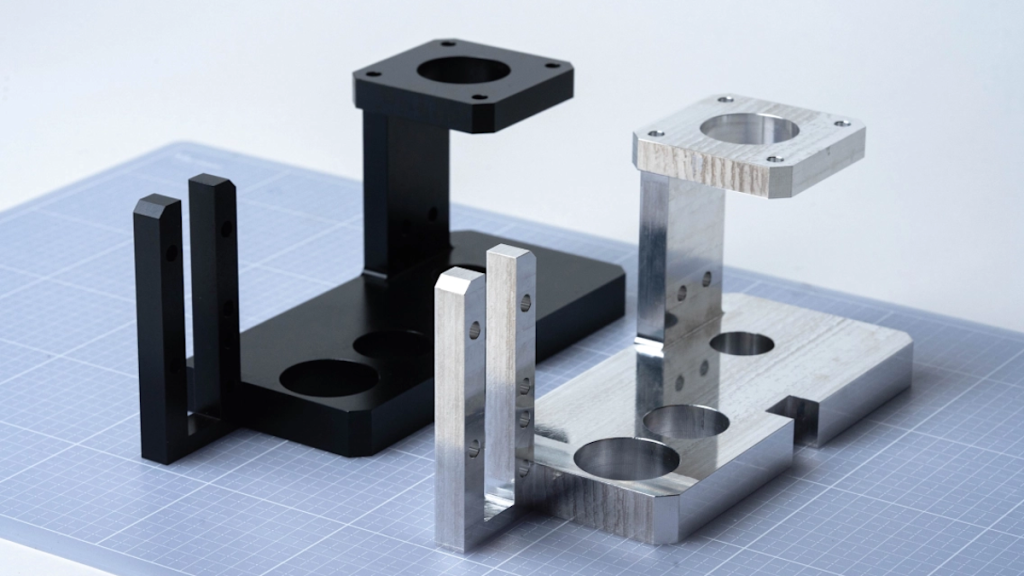

Gallery of CNC machined parts

Here’s a small selection of the CNC machined prototypes

and end-use parts we’ve produced for our customers.

Aluminium 7075-T6

Peek

Aluminium 7075-T6

Stainless 6080

CNC machining surface finishes

We can instantly quote a wide variety of post-machining surface finishes.

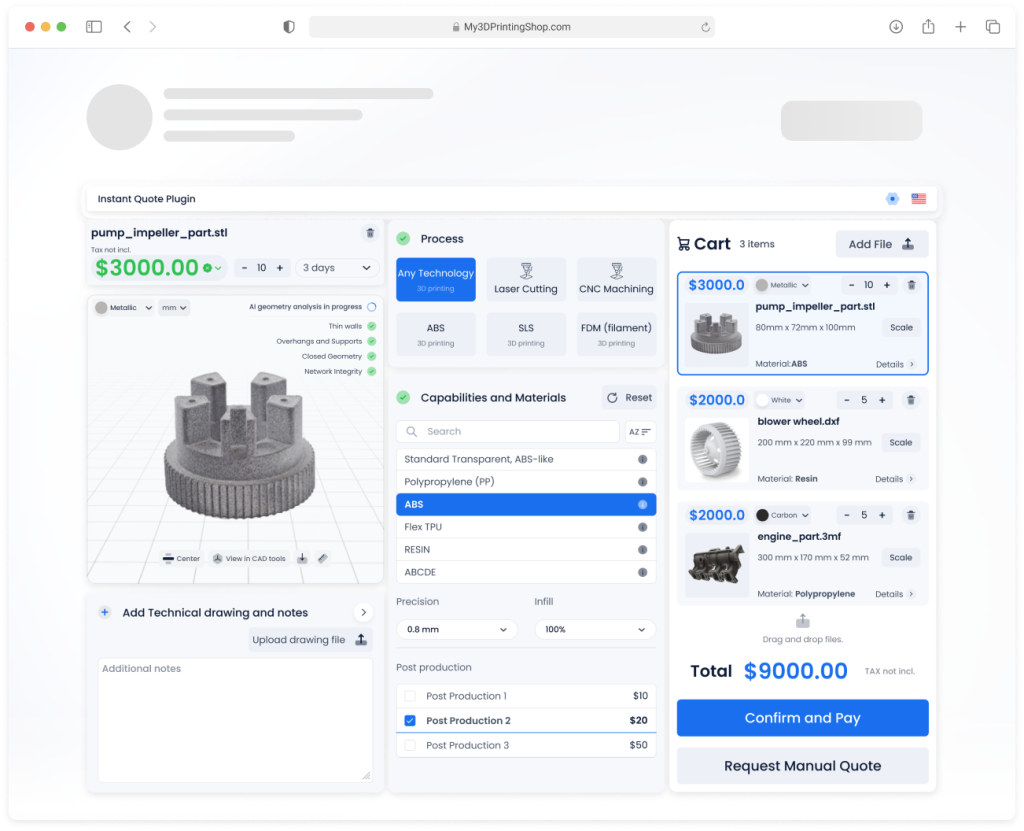

Instant, online CNC quotes

Instead of traditional, rules-based quoting, we use machine learning algorithms to compare your CAD to millions of previously manufactured parts and generate a quote instantly.

- Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

- Price updates in real-time as you change materials, lead time, etc..

- No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Our ordering process

Upload CAD file

Securely upload your part design to our online quote builder

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Receive instant quote

Upload your CAD to our online quoting platform

Manufacturing

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our CNC Machining service has been rated 4.9/5

{place2}

Over 294 customers are satisfied with our CNC Machining service.

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

–

“Great experience . Great work.”

–

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

“The service was done at a good quality with a reasonable price. Fast delivery as expected”

Consistent quality, every time with our CNC

machining service

SeekMake Network guarantees the quality of every part we manufacture. Along with thoroughly vetting the manufacturing partners we work with, every order is dimensionally and visually inspected according to The SeekMake Network Standard. Globally manufactured orders also undergo a second inspection at our cross-docks in Amsterdam and Chicago when necessary.

Instant pricing

Get instant quotes with all pricing information upfront

The SeekMake Network Standard

We use a rigorous set of protocols and procedures to maintain quality

Specialized network

Get access to cutting-edge capabilities and limitless capacity

From CNC rapid prototyping to production

Rapid prototyping

Our platform accelerates prototyping development cycles by reducing pre-production admin from weeks to minutes:

- Instant quotes

- Instant DFM feedback

- Online quote and order management

- Live delivery tracking

Our intuitive platform automates the ordering process, but if you ever need us, we’re here to help.

Production

For production orders, we have full-service teams ready to guarantee identical specs on every order for the best unit price:

- Dedicated project managers in your time zone

- Application engineers for DFM cost optimizations

- First Article Inspection (FAI)

Manufacturing is about relationships, so we have staff on the ground wherever you are to help make sure everything runs smoothly and on time, every time.

Our distributed network of CNC machine shops

We offer you the capacity and capabilities of dozens of local and global machine shops,

with the ease of dealing with one. You get the experience and specialization of all our partner shops,

we handle all the communications, delivery, quality control and customs.

CNC machining factory in the USA

CNC machining factory in China

CNC machining factory in China

Parts in 1 day in {place2}

SeekMake and its network work together to bring you the world’s most comprehensive manufacturing solution. While the network can provide a large breadth of capabilities, SeekMake’ factories offer expedited manufacturing with automated in-house machines for the industry’s fastest lead times.

How we compare to traditional CNC machine shops

As part of SeekMake’ global services, we are your comprehensive manufacturing solution from prototype to production. Here’s how we differ from traditional machine shops:

- We have an incredibly broad range of capabilities–much more than most individual shops.

- In most cases our quotes are instant. Request as many quotes as you like to find the best solution for your project.

- There is no minimum order quantity.

- We can scale with you from quick-turn prototypes with 1-day lead times to millions of production parts with volume pricing.

- We leverage a global network to guarantee competitive pricing on every order.

We machine custom parts for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Get started with our CNC machining service

We offer you the capacity and capabilities of dozens of local and global machine shops,

with the ease of dealing with one. You get the experience and specialization of all our partner shops,

we handle all the communications, delivery, quality control and customs.

How do you start CNC machining parts with SeekMake Network?

SeekMakeNetwork combines its instant quoting tool and a global network of CNC machining centers to manufacture custom parts for applications ranging from rapid prototyping to serial production. You can use SeekMake Network’s digital manufacturing platform to source high quality, complex metal and plastic parts efficiently and reliably.

To start sourcing CNC-machined parts with SeekMake Network, simply upload a CAD file and technical drawing to our free quote building tool. You’ll either receive an instant CNC quote and be able to start production in only a few clicks, or you’ll be directed to one of our engineers for potential design for manufacturability (DFM) guidance.

How does SeekMake Network's custom CNC machining service work?

CNC machining is the most common subtractive manufacturing technology available today and an optimal method for producing custom metal and plastic parts for prototyping and production applications. Using CAD (computer-aided design) modeling software and G-code, CNC milling and CNC turning machines remove material from a solid workpiece with precision and speed.

CNC machines manufacture robust parts with tight tolerances and a range of impressive material properties (mechanical and chemical). Our custom CNC machining service is ideal for one-off jobs and low-to-medium volume production, thanks to automation and high repeatability.

Hundreds of CNC machining shops in one network

SeekMake Network connects you with experienced manufacturing partners operating 2-, 3-, and 5-axis CNC machines. Our machinists work with a huge range of materials, including aluminum, stainless steel, mild, alloy & tool steels and production-grade polymers. We also offer many different surface finishing options such as anodizing, electroless nickel plating, powder coating and custom part marking with laser engraving and silk screening. For certain types of parts, you can also request rapid machining to get your parts manufactured in as few as five days.

FAQ's about CNC machining service

We guarantee that our manufacturing partners follow ISO 2768 standards for all CNC machined parts. Parts machined with metal will follow ISO 2768-m (medium) or ISO 2768-f (fine). Parts machined with plastics will follow 2768-m (medium). Geometric tolerances down to ± 0004 in. (0.010 mm) are possible but must be clearly indicated in technical drawings. We can achieve tighter tolerances on shafts with up to H7 fits with manual quoting and on occasion tighter.

At Protolabs Network we offer CNC milling (3-axis, 3+2-axis and 5-axis) and turning. Milled parts can be machined up to 2000 x 1500 x 200 mm (78.7 x 59.0 x 7.8 in.) for 3/3+2 axis CNC milling. For 5-axis milling, the maximum part size is 650 x 650 x 300 mm (25.5 x 25.5 x 11.8 in.). The maximum diameter for CNC turning is 431mm (17 in.), length 990 mm (39 in). Minimum part dimensions recommended are around 0.39 x 0.39 x 0.39 in. (10 x 10 x 10mm).The minimum for feature dimensions is 0.5 mm.

We are limited to a 1000 mm (39 in.) maximum size for parts on our platform. If you need higher dimensions, you can place the request through your account manager.

Deburring and edge breaking are standard procedures for all CNC machined parts. If there are any critical edges that should be left sharp, they must be clearly indicated in technical drawings. Surfaces will be free of defects such as scratches, dents, stains, blemishes, hanging marks, minor defects. Surfaces indicated as critical (primary (a) side, as indicated on the technical drawing) will be free of mill steps and other marks. For the secondary (b) side, minor hanging marks and up to 2 minor defects are acceptable. A number of post-processing and finishing methods can be applied to improve the surface roughness, visual properties and wear resistance of machined parts.

We use machine learning algorithms to calculate the exact cost of any machinable part directly from a CAD file, based on millions of CNC machining orders we’ve previously processed. No more waiting for technicians to get back to you via email, we can generate an exact quote for you instantly (well, in about 5 seconds).

This means you always know the price up front. Simply upload a CAD file to generate a quote: get an instant CNC machining quote. Our quotes are completely free, you only need to create an account so we can protect your IP.

It’s so easy to use that we encourage mechanical engineers to use it constantly as they optimize their designs for cost. Whenever you’ve made a new design iteration, simply load both the old and the new design into our quoting tool and see if the price is different.

This technology means our manufacturing partners also don’t need to do their own machining quotes, which means less overhead for them. This makes the whole process less expensive, which translates into lower prices for our customers.

The main costs associated with CNC machining can be grouped into machining time, start-up costs, material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

The best way to reduce machining time is to design features that can be machined quickly, for example by choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length and designing holes with standard sizes.

Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

Start-up costs can be reduced by reducing the number part rotations or repositioning required to finish the part, for example by separating geometries into multiple parts that can be assembled later.

Feature costs can be reduced by only using tolerances when strictly necessary, removing all text & lettering, and avoiding multiple surface finishes.

We use algorithms to identify the best manufacturer in our network for your specific order, based on their proximity to you, their experience with similar parts and their available capacity right now. This allows us to balance our customers’ demands for speed, cost and quality better than ever before.